- Home

- Our Products

- Rack Roll Forming Machine

- Racking Upright Roll Forming Machine

- Heavy Duty Rack Upright Roll Forming Machine

Heavy Duty Rack Upright Roll Forming Machine

- General Details

- Machine Video

- Comments

Heavy Duty Rack Upright Roll Forming Machine

Introduction of Heavy Duty Rack Upright Roll Forming Machine

Heavy Duty Rack Upright Roll Forming Machine is specially designed for producing warehouse rack upright for automatic stereoscopic warehouse, also called AS/RS(Automated Storage and Retrieval System. The whole heavy duty rack upright roll forming machine is composed of decoiler, main forming machine, hydraulic cutting, control box, outer table. The upright thickness and dimension sizes all can be adjustable and customized, as per customer requirement.

Introduction of AS/RS(Automated Storage and Retrieval System

AS/RS stands for Automated Storage and Retrieval System. It’s a computer-controlled system for automatically depositing and retrieving loads from defined storage locations. AS/RS systems are typically used in warehouses and distribution centers to efficiently manage inventory and optimize storage space.

These systems often consist of a variety of computer-controlled technologies, such as conveyors, automated guided vehicles (AGVs), robotic arms, and high-bay storage racks. They use software to manage inventory, track items, and optimize storage space, making them essential for large-scale operations where efficiency and accuracy are critical.

Wuxi Sanli Machinery is specialized manufacturer of roll forming machines focused on racking industry, including rack upright roll forming machine, rack beam roll forming machine, rack bracing roll forming machine, rack shelf roll forming machine, rack shutter rail roll forming machine, etc, for the last 30 years. In China, about 80% of the racking factories have our machines.

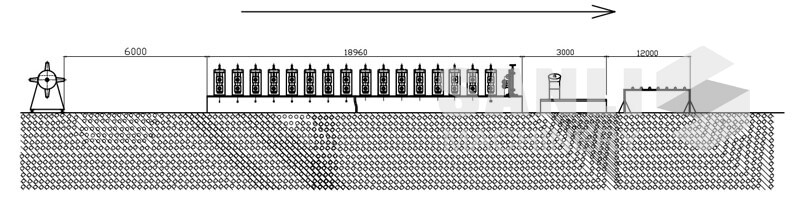

Machine Layout of Heavy Duty Rack Upright Roll Forming Machine

Decoiling –roll forming – hydraulic servo follow cutting – Out table

Machine List of Heavy Duty Rack Upright Roll Forming Machine

| 1 | 5 Ton Hydraulic Decoiler | 1 Set |

| 2 | Main Roll Forming Machine | 1 Set |

| 3 | Controller | 2 Sets |

| 4 | Hydraulic Station | 1 Set |

| 5 | Control Panel Box | 1 Set |

Main Specifications of Warehouse Rack Upright Roll Forming Machine

• Material thickness: 3.5mm

• Roller stations: 30stations

• Roller material:Cr12, HRC58-62°

• Shaft diameter:Ф90mm,material

• Main motor power: 22Kw*3sets

• Hydraulic cutting power: 15 Kw

• Forming speed: 5-15m/min

• Drive way: drive by gearbox

• PLC Control box: Delta, Taiwan

• Encoder: Omron, Japan

• Inverter: Mitsubishi, Japan

• Power supply: 380V, 50Hz, 3Phase ( as per requirement)

Machine Photo

Q&A

1.Q: What experience do you have in producing heavy duty rack roll forming machine?

A: Our company focused on racking roll forming machine production for last 30 years, in China, more than 80% of the racking factories use our rack machines, in the racking center of Nanjing city, we have more than 300 customers.

2. Q:How many sizes can be produced in one rack roll forming machine?

A: This heavy duty rack upright roll forming machine is designed with cassette structure, that last five roller stations for height is with cassette structure, so you can produce rack height of 95mm, 115mm, 135mm, 150mm all in one machine by just change the cassette, very easy operation.

3. Q: What is your machine speed?

A: Machine roll forming speed is 0-15m/min, adjustable.

4. Q: What is life time of this rack upright roll forming machine?

A: Our rack upright roll forming machine is designed with most strong structure of casting frame structure with gear box drive, so our machine life time usually can be more than 10 years, some of our old customers is running our machine for more than 15 years, the machine is still running smoothly.

5. Q: What is your after-sales service system?

A: We will send engineers to our customer’s workshop for machine installation and commissioning and training if customer require. And we provide whole life service to our customers, if there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.